LOMA

LOMA is developed to improve operational efficiency and productivity in the industry.

LOMA aims to help users’ business achieve growth by providing end-to-end Iot solution

,which is designed aligning with customer’s pain point and requirements.

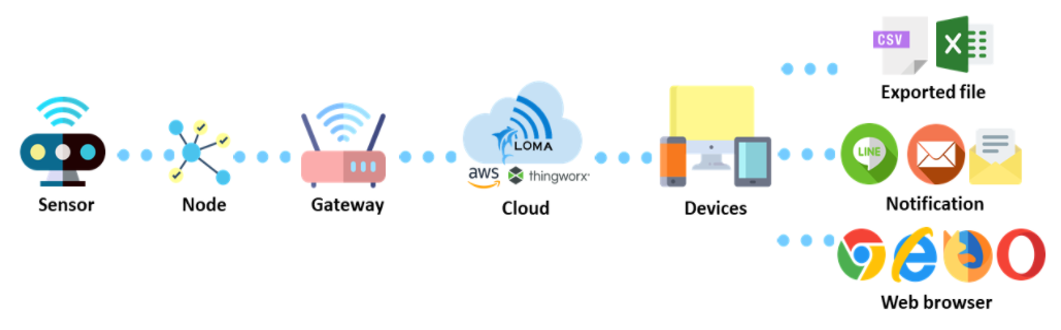

LOMA monitoring system provides real-time data of machine and environment. Users can monitor ongoing status via web browser on their devices (mobile phone, tablet, and laptop etc.) when being off-site which make work life easier and more flexible.

LOMA sent notification to users’ email, SMS or LINE before status of machine or environment is nearly going out of set range. This function can prevent critical problem from happening, and also prevent downtime. It helps every component function smoothly and decline hidden cost from maintenance and production waste.

Make work life easier by keeping data on world safest cloud server which offer limitless storage capacity and instant accessibility. Moreover, it helps employees who are in different geographies to collaborate in a highly convenient and secure manner. Also, users will save cost and space for hardware investment, and collected data can utilize to analyze for cost saving, energy saving and resource management planning.

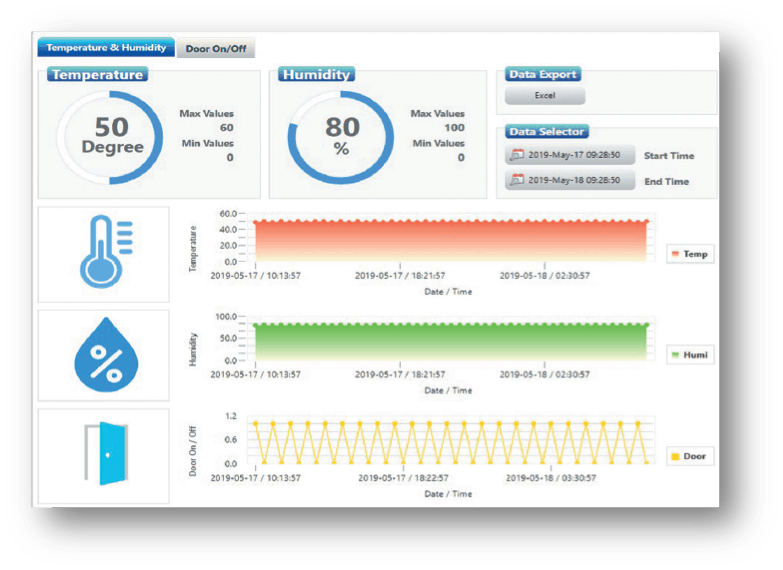

CSV file allows you to utilize data with many different business programs such as Microsoft Excel. Output data is editable so users can transtorm data into any kind of formats, such as graph, to reach its effectiveness Also, users will save cost and space for hardware investment, and collected data can utilize to analyze for cost saving, energy saving and resource management planning.

LOMA serves advance lot solution service aligned with user’s requirements

such as Industry 4.0 transformation, OEE, ERP and TMP.

LOMA provide you accurate data, unlike data record manually, leads to accurate report and analyzing result. This data base is key resource to create effective operating plan. Another benefit is the record of precise data can be an evidence to certify quality control standard.

LOMA sent notification to users’ email, SMS or LINE before status of machine or environment is nearly going out of set range. This function can prevent critical problem from happening, and also prevent downtime. It helps every component function smoothly and decline hidden cost from maintenance and production waste.

Collected data is utilized for creating Cost & Energy saving plan, preventive maintenance plan resource management plan

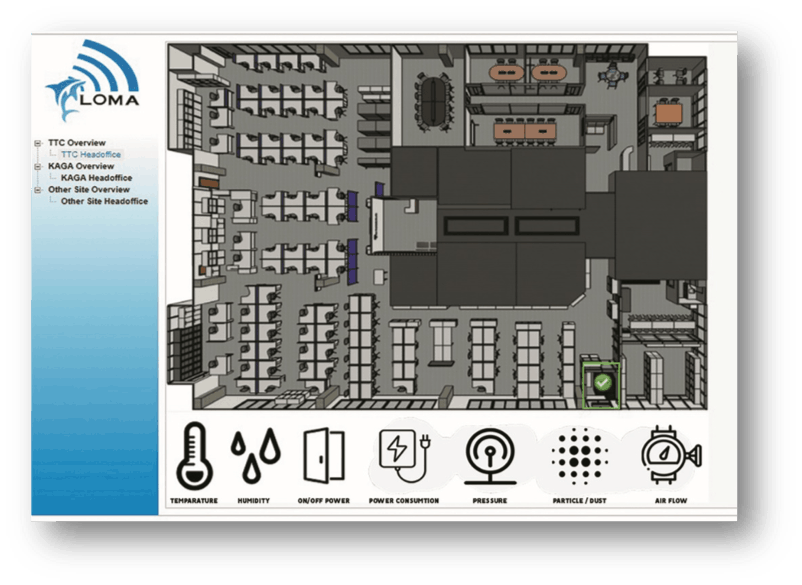

LOMA’s dashboard is designed to be friendly for everyone, not only expertise. Cloud server storage allow user to see the status of many places in one screen, conversely, while many users from different places and access to same data set.

LOMA is end-to-end technology platform designed for the industrial Internet of Things. Users can use LOMA platform to generate Iot solution as needed.

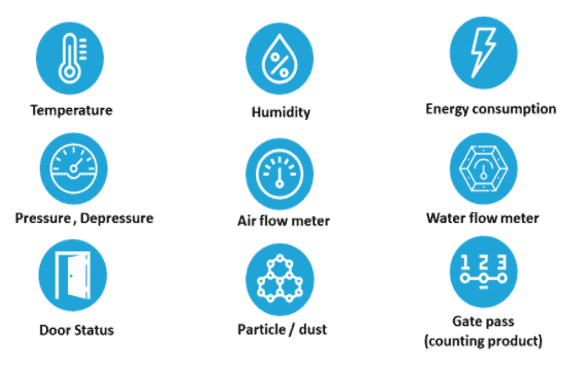

Many types of measurement tools(sensor) can be provided as the requirement.

Here are some exsamples.

LOMA’s dashboard is user-friendly and customizable as needed.

Users can create the format that is the most practical for their business form.

Standard dashboard displays real-time data, historical data which provide an immediate visual record of data. Also, period data shown, value range, notification receiver account can be set on dashboard.

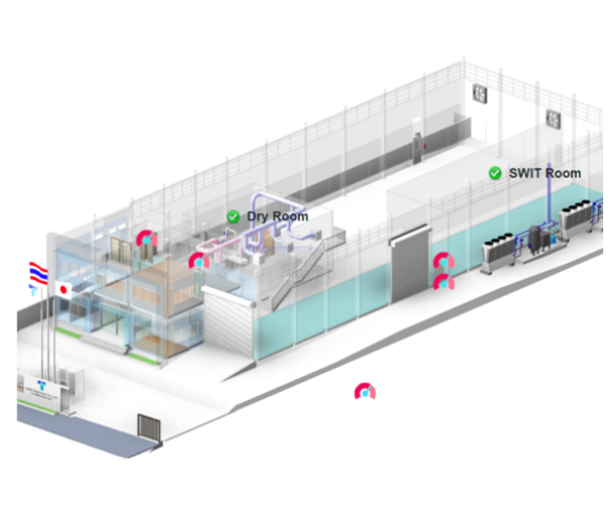

Standard UI has same fundamental of standard UI, but what they have in advance is 3D technology which provide users reality visual and accurate measurement even in a very complex structure that difficult to access.

LOMA can with more than 150 industrial protocols which mean they can integrate with almost of all type of sensors in the market.

ThaiTakasago Engineer Team who has expertise in M&E (Mechanical and electrical systems) together with IT support team from our partner, MAT, is the perfect combination to create the solution for your facility.

Copyright © www.thaitakasago.co.th, All Right Reserved.